Signal Control Centre Maintenance Staffing Assessment

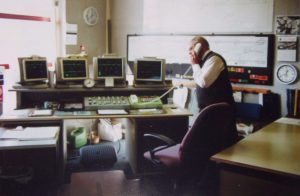

This was a challenging manpower assessment project that was difficult to perform using traditional industrial engineering methodologies due to the highly specialized nature of maintenance crafts within a control centre. The maintenance crafts were divided into different specialities where although the core skills were somewhat similar, the specific knowledge, high level of accuracy, and low latency required for attending to emergency situations essentially alone meant that it was not really possible to cross-train these highly technical employees to cover one another’s jobs. The “emergency response” nature of their jobs also meant that there will necessarily be downtime within their day if no technical faults were reported on their shift. It was simply not possible to enumerate all tasks performed and probability of having to perform that task on a given shift. We took an approach that assessed their “base workload”, that is, tasks related to preventative maintenance, and using probabilities of failures informed by historical failure data we added in the employee-hours required for emergency response, then we assigned the shifts and locations such that as much coverage was provided as possible given the resourcing constraints by assigning the preventative tasks across multiple shifts and at multiple locations (where feasible). Our analytical results formed the basis for justifying an expansion in the planned staffing levels in these highly technical disciplines because we were able to demonstrate that these sophisticated control systems required this level of manning for proper maintenance and incident coverage.

This was a challenging manpower assessment project that was difficult to perform using traditional industrial engineering methodologies due to the highly specialized nature of maintenance crafts within a control centre. The maintenance crafts were divided into different specialities where although the core skills were somewhat similar, the specific knowledge, high level of accuracy, and low latency required for attending to emergency situations essentially alone meant that it was not really possible to cross-train these highly technical employees to cover one another’s jobs. The “emergency response” nature of their jobs also meant that there will necessarily be downtime within their day if no technical faults were reported on their shift. It was simply not possible to enumerate all tasks performed and probability of having to perform that task on a given shift. We took an approach that assessed their “base workload”, that is, tasks related to preventative maintenance, and using probabilities of failures informed by historical failure data we added in the employee-hours required for emergency response, then we assigned the shifts and locations such that as much coverage was provided as possible given the resourcing constraints by assigning the preventative tasks across multiple shifts and at multiple locations (where feasible). Our analytical results formed the basis for justifying an expansion in the planned staffing levels in these highly technical disciplines because we were able to demonstrate that these sophisticated control systems required this level of manning for proper maintenance and incident coverage.