Tag: benchmarking

State of Good Repair Resource Requirements Assessment

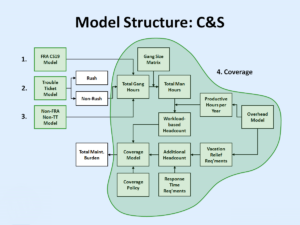

On behalf of a major regional passenger rail operator, as part of ongoing efforts to rightsize the Maintenance of Way (MOW) workforce, we led a team of production planners and analysts to conduct a zero-based budget assessment in all major MOW areas at the maintenance headquarters, gang, shift, and craft levels. In this study, we enumerated each railway infrastructure system that must be maintained by MOW personnel, including periodic and preventative (FRA, FTA, and non-regulatory) maintenance plans for each system, and determine the repair maintenance workload based on both historical trouble ticket data as well as asset quantities and probabilities of failure. We also included major repair workloads for such unforeseen situations as cable degradation, grade crossing accidents, long-term concrete and steel degradation, and interactions between asset renewal activities in the C&S, Track, and Power depts. The study recommended changes in personnel strength in a number of key crafts at several locations, to reduce overtime requirements, ensure that major project backlogs can be addressed in an efficient manner, and to provide preventative maintenance for new assets expected to be commissioned following major capital investment projects.

On behalf of a major regional passenger rail operator, as part of ongoing efforts to rightsize the Maintenance of Way (MOW) workforce, we led a team of production planners and analysts to conduct a zero-based budget assessment in all major MOW areas at the maintenance headquarters, gang, shift, and craft levels. In this study, we enumerated each railway infrastructure system that must be maintained by MOW personnel, including periodic and preventative (FRA, FTA, and non-regulatory) maintenance plans for each system, and determine the repair maintenance workload based on both historical trouble ticket data as well as asset quantities and probabilities of failure. We also included major repair workloads for such unforeseen situations as cable degradation, grade crossing accidents, long-term concrete and steel degradation, and interactions between asset renewal activities in the C&S, Track, and Power depts. The study recommended changes in personnel strength in a number of key crafts at several locations, to reduce overtime requirements, ensure that major project backlogs can be addressed in an efficient manner, and to provide preventative maintenance for new assets expected to be commissioned following major capital investment projects.

Related Publications/Presentations:

Cyclical Track Replacement Process Improvements

For a railroad infrastructure owner in the United States, we led an effort to examine work constraints resulting in less than ideal throughput of cyclical track program rail and wood tie replacement in continuously-welded rail (CWR) territory by a mechanized track gang. We utilized an eight-step framework consisting of organization, procedure, personnel, time study, rate analysis, utilization analysis, rightsizing, and benchmarking to understand and improve the work process. In the current line-up of track machines, production throughput varied significantly depending on factors such as local track characteristics (e.g. spike versus Pandrol clips), and operator skill. We recommended addition of drilling and screw lagging machines, which could improve gang throughput on curve territory. In this setting, the root cause of low machine utilization are the daily setup/preparation and tear down burden, and mobilization and demobilization at each site. We further recommended task-specialized gangs to ensure optimal machine and personnel mix, sequential work planning to improve machine utilization, and establishment of extra lists based on craft rather than providing protect coverage within each gang.

For a railroad infrastructure owner in the United States, we led an effort to examine work constraints resulting in less than ideal throughput of cyclical track program rail and wood tie replacement in continuously-welded rail (CWR) territory by a mechanized track gang. We utilized an eight-step framework consisting of organization, procedure, personnel, time study, rate analysis, utilization analysis, rightsizing, and benchmarking to understand and improve the work process. In the current line-up of track machines, production throughput varied significantly depending on factors such as local track characteristics (e.g. spike versus Pandrol clips), and operator skill. We recommended addition of drilling and screw lagging machines, which could improve gang throughput on curve territory. In this setting, the root cause of low machine utilization are the daily setup/preparation and tear down burden, and mobilization and demobilization at each site. We further recommended task-specialized gangs to ensure optimal machine and personnel mix, sequential work planning to improve machine utilization, and establishment of extra lists based on craft rather than providing protect coverage within each gang.

Related Publications/Presentations:

Track and Power Outage Planning Process Review

For a major commuter railroad, we were tasked to review the processes utilized in planning for, and resolving conflicts inherent in, track outages required for routine maintenance work and major capital projects. The remit also included a review of software tools that could be utilized, scheduling techniques that could provide longer windows of outage opportunities, and benchmarking with other passenger rail operators to identify possible improvements. We attended many track outage coordination meetings and concluded generally that existing processes were effective as long as participants had the necessary level of operations/construction knowledge, sufficient information about the (maintenance and capital) work to be accomplished, good understanding of their own resource requirements and availability, and properly communicate this information succinctly. Although other rail operators utilized web-based software for more detailed advance planning or had a more regimented process that reduced possibilities of errors or misunderstandings, they also forfeit some flexibility our client had available in terms of responding to short-term changes of plan due to e.g. last minute resourcing or weather-related issues. The scheduling rules for outage request/approvals, and base schedules when work was likely to occur, were written as to generally avoid having to issue a revised or special public timetable to accommodate any reasonably foreseeable work, which preserves operational flexibility for both maintenance work scope changes and in case of train delays due to incidents. However, we recommended that special schedules should be issued to accommodate major projects, as to improve the bandwidth available for project work and reduce both the instances of outages required and overall project costs. As a follow-up, we were tasked to review the power outage planning process within the context of accelerating a major investment programme; our findings were broadly similar, and their implementation resulted in faster rate of progress in the project.

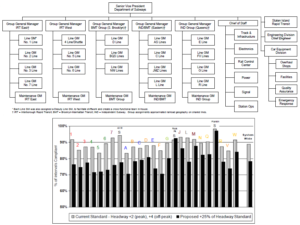

Developing Performance Measures for a New Management Framework

For a large public transit agency, we developed a series of aggregate performance measures using a balanced scorecard framework to support the roll-out of an operations management restructuring programme designed to provide a single point of accountability for service on each rail line. The rail lines have shared track segments where they share stations, and several lines would share major maintenance assets such as workshops. Additionally, trains may be subject to diversion onto other lines in case of operational perturbations, which in some cases are not an unusual occurrence. It was, therefore, necessary to report the composite performance of each line by allocating performance results which may be measured by station, by track segment, or for shared vehicle fleets. We developed a weighting scheme by utilizing usage statistics by line, and by utilizing existing “performance priority” data from a prior customer survey to inform which aspects of performance is more important to the customer (e.g. station cleanliness versus car reliability). This resulted in a composite performance measure which allowed overall performance of all lines to be presented in rank order. While the analytics behind the weighting scheme are not complicated, the most challenging aspect of this project was to gain acceptance of the proposed performance measures amongst the new line general managers whose performance would be so adjudicated, and we consider their acceptance of our proposal an important achievement.

For a large public transit agency, we developed a series of aggregate performance measures using a balanced scorecard framework to support the roll-out of an operations management restructuring programme designed to provide a single point of accountability for service on each rail line. The rail lines have shared track segments where they share stations, and several lines would share major maintenance assets such as workshops. Additionally, trains may be subject to diversion onto other lines in case of operational perturbations, which in some cases are not an unusual occurrence. It was, therefore, necessary to report the composite performance of each line by allocating performance results which may be measured by station, by track segment, or for shared vehicle fleets. We developed a weighting scheme by utilizing usage statistics by line, and by utilizing existing “performance priority” data from a prior customer survey to inform which aspects of performance is more important to the customer (e.g. station cleanliness versus car reliability). This resulted in a composite performance measure which allowed overall performance of all lines to be presented in rank order. While the analytics behind the weighting scheme are not complicated, the most challenging aspect of this project was to gain acceptance of the proposed performance measures amongst the new line general managers whose performance would be so adjudicated, and we consider their acceptance of our proposal an important achievement.

Related Publications/Presentations:

International Metro Benchmarking on Governance Frameworks

As a spin-off of a national research and training program, we were tasked to determine through publicly available information why many South East Asian transit properties visited by the program delegation have reportedly positive cash flows, i.e. are “profitable”. We found through a detailed comparative analysis of demand densities, asset utilization, regulatory frameworks, performance regimes, operating practices, and softer cultural factors that in fact only the “prudent commercial” portion of the Hong Kong Mass Transit Railway were profitable in the purest sense where farebox revenues exceeded operating expense plus the long term cost of capital renewal. In other cities, the operators are more akin to concessioned carriers or management contractors where at least some infrastructure costs were separated from the operating entity using a variety of financial devices. These systems also received various real estate grants in transactions reminiscent of U.S. “land grant” railroads and have more autonomy and commercial freedom to develop their transit-oriented property holdings. Large metro systems in the U.S. had made network design choices with consequences in density and utilization, which explain some of the higher productivities observed in Asia. We conclude that direct comparisons in performance, profitability, and productivity should be avoided unless care is taken to analyze impacts of governance, social contexts, design criteria, and reasons for these differences. Nonetheless, we believe benchmarking exercises can yield valuable insights for operations improvement under prevailing local constraints.

As a spin-off of a national research and training program, we were tasked to determine through publicly available information why many South East Asian transit properties visited by the program delegation have reportedly positive cash flows, i.e. are “profitable”. We found through a detailed comparative analysis of demand densities, asset utilization, regulatory frameworks, performance regimes, operating practices, and softer cultural factors that in fact only the “prudent commercial” portion of the Hong Kong Mass Transit Railway were profitable in the purest sense where farebox revenues exceeded operating expense plus the long term cost of capital renewal. In other cities, the operators are more akin to concessioned carriers or management contractors where at least some infrastructure costs were separated from the operating entity using a variety of financial devices. These systems also received various real estate grants in transactions reminiscent of U.S. “land grant” railroads and have more autonomy and commercial freedom to develop their transit-oriented property holdings. Large metro systems in the U.S. had made network design choices with consequences in density and utilization, which explain some of the higher productivities observed in Asia. We conclude that direct comparisons in performance, profitability, and productivity should be avoided unless care is taken to analyze impacts of governance, social contexts, design criteria, and reasons for these differences. Nonetheless, we believe benchmarking exercises can yield valuable insights for operations improvement under prevailing local constraints.

Related Publications/Presentations:

Shared Use of Railroad Infrastructure: Practical Field Research

For a national transit research program, we were responsible for researching and writing a report on the shared use of railroad infrastructure by non-compliant light rail vehicles. At that time, the use of Federal Railroad Administration (FRA) waivers for operating light rail cars on general system of railroads was in its nascent years, and the concept of temporal or spatial separation was still in development. As part of this project, we visited a number of properties that have existing waivers. Through interviews with stakeholders, technical specialists, and transit managers, we determined the essential elements and conditions that allowed the system to operate safely and likely receive FRA waiver approval. We identified suitable train control technologies, their performance, costs, and operational impacts. We also determined common procedural and regulatory approaches, and methods for costsharing, staffing, and emergency recovery.

For a national transit research program, we were responsible for researching and writing a report on the shared use of railroad infrastructure by non-compliant light rail vehicles. At that time, the use of Federal Railroad Administration (FRA) waivers for operating light rail cars on general system of railroads was in its nascent years, and the concept of temporal or spatial separation was still in development. As part of this project, we visited a number of properties that have existing waivers. Through interviews with stakeholders, technical specialists, and transit managers, we determined the essential elements and conditions that allowed the system to operate safely and likely receive FRA waiver approval. We identified suitable train control technologies, their performance, costs, and operational impacts. We also determined common procedural and regulatory approaches, and methods for costsharing, staffing, and emergency recovery.

Related Publications/Presentations:

- Shared Use of Railroad Infrastructure with Noncompliant Public Transit Rail Vehicles: A Practitioner’s Guide

- Business Model for Commingled Operations of Freight and Non-FRA-Compliant Passenger Rail Services

Note: Alex Lu performed this work as an employee of another firm.

Field Thermite Rail Welding Productivity Studies

We performed an analysis of work assignments, processes, and equipment utilized by welding gangs in different districts on a major suburban railway to identify opportunities for productivity improvements using a six-sigma type methodology. The prevailing wisdom at the time was that certain welding foreman were more “productive” than others, which led to dramatically different weld count outputs per period. Through field observation and data analysis, we discovered that in fact there were many factors contributing to the differences in welding outputs: (1) certain gangs were assigned unreliable hirail equipment; (2) due to nature of their assignments, some gangs found it easier and quicker to obtain necessary track time; (3) gang productivity were much higher when multiple rail joints needed to be welded within the same signal block; (4) no formal process existed for providing replacement welding foreman or qualified welder in case of vacation or absence; (5) differences in weather between geographic regions contributed to number of days when welding gang can safely work. The minor differences in methods, equipment type, and worker habits did not materially contribute to the differences in observed rates of output*. Based on this study, we recommended that a systemwide “extra board” of welders and foremen be established to provide cover for necessary absences (which could be utilized on spare equipment as an additional gang when there were no absences), that assignments should prioritize those temporary joints within the same block and on the same track, that new hirail equipment be procured for three gangs with least reliable equipment (keeping one best set for spare), and a project be initiated for testing field electric-arc welding equipment in place of chemical “pot” welding. The new hirail equipment improved welding productivity significantly as soon as they were commissioned.

We performed an analysis of work assignments, processes, and equipment utilized by welding gangs in different districts on a major suburban railway to identify opportunities for productivity improvements using a six-sigma type methodology. The prevailing wisdom at the time was that certain welding foreman were more “productive” than others, which led to dramatically different weld count outputs per period. Through field observation and data analysis, we discovered that in fact there were many factors contributing to the differences in welding outputs: (1) certain gangs were assigned unreliable hirail equipment; (2) due to nature of their assignments, some gangs found it easier and quicker to obtain necessary track time; (3) gang productivity were much higher when multiple rail joints needed to be welded within the same signal block; (4) no formal process existed for providing replacement welding foreman or qualified welder in case of vacation or absence; (5) differences in weather between geographic regions contributed to number of days when welding gang can safely work. The minor differences in methods, equipment type, and worker habits did not materially contribute to the differences in observed rates of output*. Based on this study, we recommended that a systemwide “extra board” of welders and foremen be established to provide cover for necessary absences (which could be utilized on spare equipment as an additional gang when there were no absences), that assignments should prioritize those temporary joints within the same block and on the same track, that new hirail equipment be procured for three gangs with least reliable equipment (keeping one best set for spare), and a project be initiated for testing field electric-arc welding equipment in place of chemical “pot” welding. The new hirail equipment improved welding productivity significantly as soon as they were commissioned.

* Note: Quality of resulting welds was outside of the scope of this study.