Tag: industrial engineering

State of Good Repair Resource Requirements Assessment

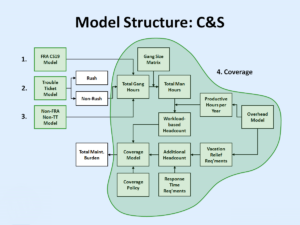

On behalf of a major regional passenger rail operator, as part of ongoing efforts to rightsize the Maintenance of Way (MOW) workforce, we led a team of production planners and analysts to conduct a zero-based budget assessment in all major MOW areas at the maintenance headquarters, gang, shift, and craft levels. In this study, we enumerated each railway infrastructure system that must be maintained by MOW personnel, including periodic and preventative (FRA, FTA, and non-regulatory) maintenance plans for each system, and determine the repair maintenance workload based on both historical trouble ticket data as well as asset quantities and probabilities of failure. We also included major repair workloads for such unforeseen situations as cable degradation, grade crossing accidents, long-term concrete and steel degradation, and interactions between asset renewal activities in the C&S, Track, and Power depts. The study recommended changes in personnel strength in a number of key crafts at several locations, to reduce overtime requirements, ensure that major project backlogs can be addressed in an efficient manner, and to provide preventative maintenance for new assets expected to be commissioned following major capital investment projects.

On behalf of a major regional passenger rail operator, as part of ongoing efforts to rightsize the Maintenance of Way (MOW) workforce, we led a team of production planners and analysts to conduct a zero-based budget assessment in all major MOW areas at the maintenance headquarters, gang, shift, and craft levels. In this study, we enumerated each railway infrastructure system that must be maintained by MOW personnel, including periodic and preventative (FRA, FTA, and non-regulatory) maintenance plans for each system, and determine the repair maintenance workload based on both historical trouble ticket data as well as asset quantities and probabilities of failure. We also included major repair workloads for such unforeseen situations as cable degradation, grade crossing accidents, long-term concrete and steel degradation, and interactions between asset renewal activities in the C&S, Track, and Power depts. The study recommended changes in personnel strength in a number of key crafts at several locations, to reduce overtime requirements, ensure that major project backlogs can be addressed in an efficient manner, and to provide preventative maintenance for new assets expected to be commissioned following major capital investment projects.

Related Publications/Presentations:

Expediting Capital Project Completion Through Root Cause Identification

On behalf of a major commuter railway, we performed a systematic study to discover the root causes of project schedule delays associated with three major Capital Projects: upgrade of a wayside signal system on an entire line, installation of passenger area cameras in a locomotive-hauled fleet, and renewal of all overhead line equipment for catenary electrification in one area. In this project, we worked on-site directly with craft personnel responsible for the work, as well as their foremen and managers, to understand their concerns with the work process, project plan, support environment, and resource assignments. For the signal project, delays were attributed to front-loaded project task sequencing, low priority assigned during the early phases, and inspection issues involving contractors, all resolved by work resequencing and more detailed project progress tracking and reporting. In the camera project, the diversity of coaching stock designs and accumulated modifications were issues, requiring multiple prototypes and steep learning curves, which were resolved with instituting periodic technical project meetings and adding more engineering staff. The catenary electrification renewal project was delayed due to contractor personnel shortage and insufficient work windows, which required the most complex solution—involving planning regular mid-week work windows and re-prioritizing more disruptive upgrade work to the weekend when longer track outages were available. In all three cases, the project managers committed to more aggressive completion schedules based on their own process improvements, resource reallocation, as well as our recommendations.

On behalf of a major commuter railway, we performed a systematic study to discover the root causes of project schedule delays associated with three major Capital Projects: upgrade of a wayside signal system on an entire line, installation of passenger area cameras in a locomotive-hauled fleet, and renewal of all overhead line equipment for catenary electrification in one area. In this project, we worked on-site directly with craft personnel responsible for the work, as well as their foremen and managers, to understand their concerns with the work process, project plan, support environment, and resource assignments. For the signal project, delays were attributed to front-loaded project task sequencing, low priority assigned during the early phases, and inspection issues involving contractors, all resolved by work resequencing and more detailed project progress tracking and reporting. In the camera project, the diversity of coaching stock designs and accumulated modifications were issues, requiring multiple prototypes and steep learning curves, which were resolved with instituting periodic technical project meetings and adding more engineering staff. The catenary electrification renewal project was delayed due to contractor personnel shortage and insufficient work windows, which required the most complex solution—involving planning regular mid-week work windows and re-prioritizing more disruptive upgrade work to the weekend when longer track outages were available. In all three cases, the project managers committed to more aggressive completion schedules based on their own process improvements, resource reallocation, as well as our recommendations.

Related Publications/Presentations:

Cyclical Track Replacement Process Improvements

For a railroad infrastructure owner in the United States, we led an effort to examine work constraints resulting in less than ideal throughput of cyclical track program rail and wood tie replacement in continuously-welded rail (CWR) territory by a mechanized track gang. We utilized an eight-step framework consisting of organization, procedure, personnel, time study, rate analysis, utilization analysis, rightsizing, and benchmarking to understand and improve the work process. In the current line-up of track machines, production throughput varied significantly depending on factors such as local track characteristics (e.g. spike versus Pandrol clips), and operator skill. We recommended addition of drilling and screw lagging machines, which could improve gang throughput on curve territory. In this setting, the root cause of low machine utilization are the daily setup/preparation and tear down burden, and mobilization and demobilization at each site. We further recommended task-specialized gangs to ensure optimal machine and personnel mix, sequential work planning to improve machine utilization, and establishment of extra lists based on craft rather than providing protect coverage within each gang.

For a railroad infrastructure owner in the United States, we led an effort to examine work constraints resulting in less than ideal throughput of cyclical track program rail and wood tie replacement in continuously-welded rail (CWR) territory by a mechanized track gang. We utilized an eight-step framework consisting of organization, procedure, personnel, time study, rate analysis, utilization analysis, rightsizing, and benchmarking to understand and improve the work process. In the current line-up of track machines, production throughput varied significantly depending on factors such as local track characteristics (e.g. spike versus Pandrol clips), and operator skill. We recommended addition of drilling and screw lagging machines, which could improve gang throughput on curve territory. In this setting, the root cause of low machine utilization are the daily setup/preparation and tear down burden, and mobilization and demobilization at each site. We further recommended task-specialized gangs to ensure optimal machine and personnel mix, sequential work planning to improve machine utilization, and establishment of extra lists based on craft rather than providing protect coverage within each gang.

Related Publications/Presentations:

Track and Power Outage Planning Process Review

For a major commuter railroad, we were tasked to review the processes utilized in planning for, and resolving conflicts inherent in, track outages required for routine maintenance work and major capital projects. The remit also included a review of software tools that could be utilized, scheduling techniques that could provide longer windows of outage opportunities, and benchmarking with other passenger rail operators to identify possible improvements. We attended many track outage coordination meetings and concluded generally that existing processes were effective as long as participants had the necessary level of operations/construction knowledge, sufficient information about the (maintenance and capital) work to be accomplished, good understanding of their own resource requirements and availability, and properly communicate this information succinctly. Although other rail operators utilized web-based software for more detailed advance planning or had a more regimented process that reduced possibilities of errors or misunderstandings, they also forfeit some flexibility our client had available in terms of responding to short-term changes of plan due to e.g. last minute resourcing or weather-related issues. The scheduling rules for outage request/approvals, and base schedules when work was likely to occur, were written as to generally avoid having to issue a revised or special public timetable to accommodate any reasonably foreseeable work, which preserves operational flexibility for both maintenance work scope changes and in case of train delays due to incidents. However, we recommended that special schedules should be issued to accommodate major projects, as to improve the bandwidth available for project work and reduce both the instances of outages required and overall project costs. As a follow-up, we were tasked to review the power outage planning process within the context of accelerating a major investment programme; our findings were broadly similar, and their implementation resulted in faster rate of progress in the project.

Organizational Development of Innovative Functions

For a number of railway organizations, we were responsible for either developing a brand new team to perform a specific function that had hitherto not been performed in-house, or for reviewing an existing group that has had its regular function and responsibilities transformed so fundamentally that a new organizational structure was needed for it to be effective. In one case, we took a unit that had various data-related responsibilities such as surveying, reporting, datamining, big data analytics, regulatory compliance, and quantitative model development, and reorganized it such that the routine data production activities were separated from the research and development activities, and from the I.T. support functions that provided the computer infrastructure on top of which all of those activities took place. For another group, we designed the decentralized organization that would together support the enterprise geographic information system (GIS) by recommending that a small core companywide GIS group was supplemented by designated representatives (both existing and new staff) embedded within various other functional units that would offer the more specialized skills required within their department (e.g. land surveying, demographic analysis, engineering, archiving) but also serve as liaison to the central unit. In another case, we developed an industrial engineering and resource review function from scratch. We also worked on an organization plan that distributed certain compliance responsibilities to subject matter experts within the appropriate areas with one manager serving as overall coordinator. In many of these cases, our organizational plan was implemented, usually with minor modifications, by the business. In one last case, we were tasked with documenting the workflow, roles and responsibilities, and business processes of an existing organization with many ad-hoc and miscellaneous tasks in a detailed and defensible way, to forestall efforts by outside forces to dismantle the unit. We ultimately contributed to their success in preventing that team from being broken up, and helped others achieve a better understanding of that group.

For a number of railway organizations, we were responsible for either developing a brand new team to perform a specific function that had hitherto not been performed in-house, or for reviewing an existing group that has had its regular function and responsibilities transformed so fundamentally that a new organizational structure was needed for it to be effective. In one case, we took a unit that had various data-related responsibilities such as surveying, reporting, datamining, big data analytics, regulatory compliance, and quantitative model development, and reorganized it such that the routine data production activities were separated from the research and development activities, and from the I.T. support functions that provided the computer infrastructure on top of which all of those activities took place. For another group, we designed the decentralized organization that would together support the enterprise geographic information system (GIS) by recommending that a small core companywide GIS group was supplemented by designated representatives (both existing and new staff) embedded within various other functional units that would offer the more specialized skills required within their department (e.g. land surveying, demographic analysis, engineering, archiving) but also serve as liaison to the central unit. In another case, we developed an industrial engineering and resource review function from scratch. We also worked on an organization plan that distributed certain compliance responsibilities to subject matter experts within the appropriate areas with one manager serving as overall coordinator. In many of these cases, our organizational plan was implemented, usually with minor modifications, by the business. In one last case, we were tasked with documenting the workflow, roles and responsibilities, and business processes of an existing organization with many ad-hoc and miscellaneous tasks in a detailed and defensible way, to forestall efforts by outside forces to dismantle the unit. We ultimately contributed to their success in preventing that team from being broken up, and helped others achieve a better understanding of that group.

Workload Study for a Critical Railway Supervisory Function

On behalf of a large metro operator, we designed a time-and-motion study using statistical sampling methodologies to determine the typical residual workload of certain field supervisors whose primary train dispatching function had been “remoted” to a centralized control center. To properly understand their workflow, we met with control center managers and reviewed their operating rules to understand their function. We also met with supervisor representatives at their work locations to ensure we capture all of the exception tasks they perform on a day-to-day basis, and factored these unusual circumstances into our study design. A team of operations managers then performed field observations on a 24/7 basis over the course of two months based on our statistical sample. Our study showed that the field supervisors, although they were actively utilized only around 30% of the time, on average several times each shift, they perform a task that could not reasonably have been performed by the train crew, which would otherwise have required a roving supervisor to be sent from another location. We also found that they fulfilled an important safety function by determining fitness-for-duty at train crew signing-on points. As a result of our study, the operations management proactively identified 40 existing messenger positions, whose function could be replaced with internal mail service, which resulted in equivalent headcount reductions.

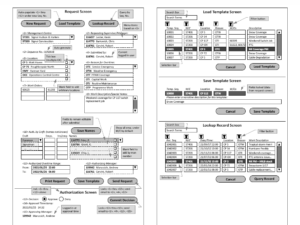

Requirements Documentation for Operations Admin Systems

We were tasked by the engineering department of a railroad to provide requirements documents, functional design, process engineering, and project management services for two operations administration systems. The first system dealt with keeping track of position advertisements, displacements, and seniority evaluations for awards in a heavily unionized environment with multiple crafts, physical characteristics qualifications, and concurrent seniorities on multiple rosters due to promotional paths. A legacy system was in place but did not provide all required functionalities. We assessed the current system and worked out the business case for complete replacement on a modernized platform versus incremental improvements. Although an agile process could have reproduced many existing functionalities very quickly, we found that certain signal systems employees had the skills to continue to improve the legacy system, access to the source code, and compilers continued to be supported by the vendor. For all those reasons, we provided project management service to deliver the required improvements using the legacy platform. The second one is used by field supervision to record overtime approvals and provide audit compliance. We worked with subject matter experts, field supervision, and executive groups to determine system requirements and develop a process that captured all necessary information without introducing undue burden on supervisory personnel. The completed project plan was turned over to corporate I.T. and compliance groups for implementation.

We were tasked by the engineering department of a railroad to provide requirements documents, functional design, process engineering, and project management services for two operations administration systems. The first system dealt with keeping track of position advertisements, displacements, and seniority evaluations for awards in a heavily unionized environment with multiple crafts, physical characteristics qualifications, and concurrent seniorities on multiple rosters due to promotional paths. A legacy system was in place but did not provide all required functionalities. We assessed the current system and worked out the business case for complete replacement on a modernized platform versus incremental improvements. Although an agile process could have reproduced many existing functionalities very quickly, we found that certain signal systems employees had the skills to continue to improve the legacy system, access to the source code, and compilers continued to be supported by the vendor. For all those reasons, we provided project management service to deliver the required improvements using the legacy platform. The second one is used by field supervision to record overtime approvals and provide audit compliance. We worked with subject matter experts, field supervision, and executive groups to determine system requirements and develop a process that captured all necessary information without introducing undue burden on supervisory personnel. The completed project plan was turned over to corporate I.T. and compliance groups for implementation.

Field Thermite Rail Welding Productivity Studies

We performed an analysis of work assignments, processes, and equipment utilized by welding gangs in different districts on a major suburban railway to identify opportunities for productivity improvements using a six-sigma type methodology. The prevailing wisdom at the time was that certain welding foreman were more “productive” than others, which led to dramatically different weld count outputs per period. Through field observation and data analysis, we discovered that in fact there were many factors contributing to the differences in welding outputs: (1) certain gangs were assigned unreliable hirail equipment; (2) due to nature of their assignments, some gangs found it easier and quicker to obtain necessary track time; (3) gang productivity were much higher when multiple rail joints needed to be welded within the same signal block; (4) no formal process existed for providing replacement welding foreman or qualified welder in case of vacation or absence; (5) differences in weather between geographic regions contributed to number of days when welding gang can safely work. The minor differences in methods, equipment type, and worker habits did not materially contribute to the differences in observed rates of output*. Based on this study, we recommended that a systemwide “extra board” of welders and foremen be established to provide cover for necessary absences (which could be utilized on spare equipment as an additional gang when there were no absences), that assignments should prioritize those temporary joints within the same block and on the same track, that new hirail equipment be procured for three gangs with least reliable equipment (keeping one best set for spare), and a project be initiated for testing field electric-arc welding equipment in place of chemical “pot” welding. The new hirail equipment improved welding productivity significantly as soon as they were commissioned.

We performed an analysis of work assignments, processes, and equipment utilized by welding gangs in different districts on a major suburban railway to identify opportunities for productivity improvements using a six-sigma type methodology. The prevailing wisdom at the time was that certain welding foreman were more “productive” than others, which led to dramatically different weld count outputs per period. Through field observation and data analysis, we discovered that in fact there were many factors contributing to the differences in welding outputs: (1) certain gangs were assigned unreliable hirail equipment; (2) due to nature of their assignments, some gangs found it easier and quicker to obtain necessary track time; (3) gang productivity were much higher when multiple rail joints needed to be welded within the same signal block; (4) no formal process existed for providing replacement welding foreman or qualified welder in case of vacation or absence; (5) differences in weather between geographic regions contributed to number of days when welding gang can safely work. The minor differences in methods, equipment type, and worker habits did not materially contribute to the differences in observed rates of output*. Based on this study, we recommended that a systemwide “extra board” of welders and foremen be established to provide cover for necessary absences (which could be utilized on spare equipment as an additional gang when there were no absences), that assignments should prioritize those temporary joints within the same block and on the same track, that new hirail equipment be procured for three gangs with least reliable equipment (keeping one best set for spare), and a project be initiated for testing field electric-arc welding equipment in place of chemical “pot” welding. The new hirail equipment improved welding productivity significantly as soon as they were commissioned.

* Note: Quality of resulting welds was outside of the scope of this study.

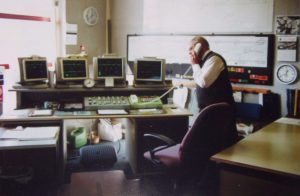

Signal Control Centre Maintenance Staffing Assessment

This was a challenging manpower assessment project that was difficult to perform using traditional industrial engineering methodologies due to the highly specialized nature of maintenance crafts within a control centre. The maintenance crafts were divided into different specialities where although the core skills were somewhat similar, the specific knowledge, high level of accuracy, and low latency required for attending to emergency situations essentially alone meant that it was not really possible to cross-train these highly technical employees to cover one another’s jobs. The “emergency response” nature of their jobs also meant that there will necessarily be downtime within their day if no technical faults were reported on their shift. It was simply not possible to enumerate all tasks performed and probability of having to perform that task on a given shift. We took an approach that assessed their “base workload”, that is, tasks related to preventative maintenance, and using probabilities of failures informed by historical failure data we added in the employee-hours required for emergency response, then we assigned the shifts and locations such that as much coverage was provided as possible given the resourcing constraints by assigning the preventative tasks across multiple shifts and at multiple locations (where feasible). Our analytical results formed the basis for justifying an expansion in the planned staffing levels in these highly technical disciplines because we were able to demonstrate that these sophisticated control systems required this level of manning for proper maintenance and incident coverage.

This was a challenging manpower assessment project that was difficult to perform using traditional industrial engineering methodologies due to the highly specialized nature of maintenance crafts within a control centre. The maintenance crafts were divided into different specialities where although the core skills were somewhat similar, the specific knowledge, high level of accuracy, and low latency required for attending to emergency situations essentially alone meant that it was not really possible to cross-train these highly technical employees to cover one another’s jobs. The “emergency response” nature of their jobs also meant that there will necessarily be downtime within their day if no technical faults were reported on their shift. It was simply not possible to enumerate all tasks performed and probability of having to perform that task on a given shift. We took an approach that assessed their “base workload”, that is, tasks related to preventative maintenance, and using probabilities of failures informed by historical failure data we added in the employee-hours required for emergency response, then we assigned the shifts and locations such that as much coverage was provided as possible given the resourcing constraints by assigning the preventative tasks across multiple shifts and at multiple locations (where feasible). Our analytical results formed the basis for justifying an expansion in the planned staffing levels in these highly technical disciplines because we were able to demonstrate that these sophisticated control systems required this level of manning for proper maintenance and incident coverage.

Journey Time Reduction Through Permanent Speed Restriction Review

On behalf of a rail infrastructure owner, we worked with in-house track, signal, and structural engineers as well as an engineering consultant to perform a review of all permanent speed restrictions on a number of high ridership corridors. We reviewed operating documents to identify civil speed restrictions throughout the study area rail network, and by using a train performance calculator, we determined those with the most impact to journey time for non-stop express trains and for local trains. Based on the result of the traction performance study, we arranged meetings with the relevant engineering areas to discover and document the reasons for each civil speed restriction. The engineering consultant provided the top speed potential given the existing track geometry and use of exceptional cant deficiency (underbalance). On occasions, multiple constraints were discovered as having contributed to one speed restriction (e.g. clearance issues or track geometry may restrict maximum authorized speeds, but even if those were removed through e.g. track realignment and resurfacing, spacing between distant and home signals may not permit speeds to be raised above a certain level unless additional work was done to relocate existing signal heads, which could trigger a signal system redesign in high density areas.) Based on the engineering findings, order-of-magnitude cost estimates for modifying the infrastructure constraints, and number of trains affected by each restriction, we produced a prioritized list of schemes to improve journey time performance in specific corridors. This programme of speed improvements formed an input to the national route utilization strategy and a basis for negotiating cost sharing agreements with train operating companies.